Solar panels, architectural sunshades, and complex multi-level rooflines are no longer the exception; they’re the norm in modern Canadian building design. While they score points for energy efficiency and visual appeal, they also create a minefield of unexpected snow and ice loads for structural engineers.

The days of simply applying a uniform specified snow load, as detailed in our structural engineer’s guide to the journey of snow, are behind us. These features introduce new risks—from concentrated loads caused by sliding snow to unique drift patterns and the often-underestimated weight of retained ice. Getting it wrong doesn’t just mean a leaky roof; it can have serious structural implications. The NBCC 2020 has evolved to address some of these, but the real devil is in the details and the commentary.

What follows is a practical, no-nonsense guide to the trickier rooftop hazards: sliding snow and lower-roof surcharges, the new solar panel provisions, and the design of effective snow retention systems and sunshades—areas where liability can be a real concern.

Sliding Snow from Upper Roofs (NBCC 4.1.6.11)

First up, the classic scenario: an upper roof shedding its snow onto a lower one. It seems simple, but it’s a dedicated load case you can’t afford to miss. NBCC 2020, Article 4.1.6.11 is our roadmap here.

The core idea is that when an upper roof slopes towards a lower roof, you have to account for the additional load from sliding snow. This is an augmentation to the drift loads you’ve already calculated for the lower roof under Article 4.1.6.5.

When Can You Ignore It?

You don’t always have to apply this load. Sentence 4.1.6.11.(2) gives you two outs:

- If the snow is physically prevented from sliding by a parapet or another “effective means”. We’ll talk more about what “effective” means in a bit.

- If the upper roof isn’t considered “slippery” (think asphalt shingles, not metal or glass) AND its slope is less than 20°.

Watch for: Be cautious with the “non-slippery” definition. A membrane roof that isn’t typically slippery can become a slip-and-slide when a thin layer of ice forms on it. The NBCC commentary mentions that freeze/thaw cycling can create multiple slip layers within the snowpack. When in doubt, it’s safer to assume it’s slippery. For a deeper understanding of the code’s distinction, you can review the “why” behind NBCC’s snow load factors.

How to Calculate the Sliding Load

If you can’t ignore it, Sentence 4.1.6.11.(3) tells you what to do. You’re going to add a portion of the snow from the upper roof onto the lower one. Here’s the simplified breakdown:

- How much snow? The load is based on half (50%) of the total weight of the uniform snow load from the sloped upper roof area. The commentary notes this is because it’s unlikely both roofs would have their full design load when sliding happens, a concept that ties into the companion action principle used in mastering NBC 2020 load combinations.

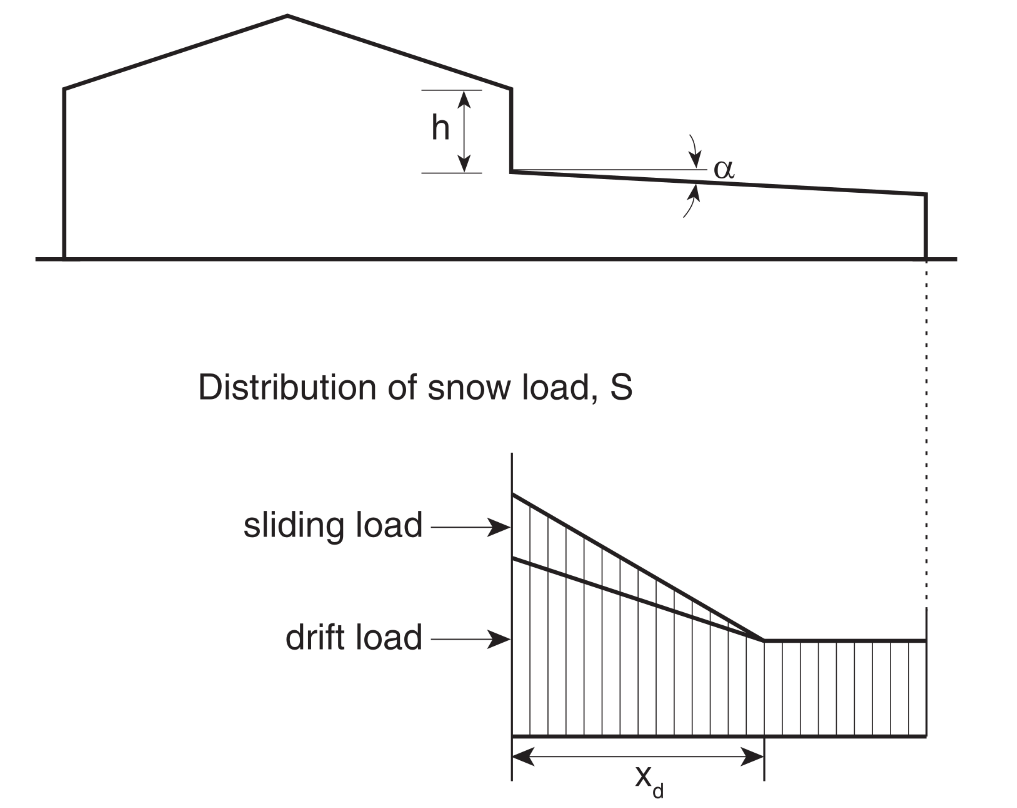

- How is it shaped? The load isn’t uniform. It’s applied as a triangular load on the lower roof, peaking right at the face of the upper wall and tapering to zero over the drift length, \(x_d\).

Source: NBCC 2020 - Figure 4.1.6.11

Source: NBCC 2020 - Figure 4.1.6.11

The New Frontier: Snow Loads and Solar Panels (NBCC 4.1.6.16)

Solar panels are everywhere now, and they completely change the snow dynamics on a roof. They are slippery, they create gaps, and they act as obstructions. The 2020 NBCC introduced Article 4.1.6.16 to give us a framework for this. This change complements the code’s new approach to handling wind loads on solar panels.

The code classifies solar panels into three main types:

- Parallel Flush: Panels installed close to the roof surface.

- Parallel Raised: Panels parallel to the roof but raised up on racking.

- Tilted: Panels installed at an angle to the roof surface (common on flat roofs).

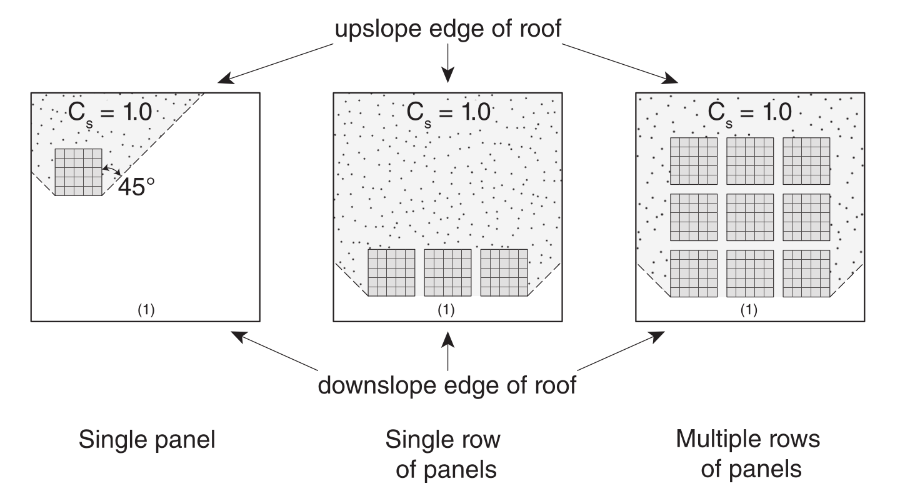

The installation of solar panels can impede the sliding of snow off a sloped roof surface. The area where sliding is considered impeded extends upslope from the panel or array at a 45° angle from the side edges. For these areas, you can’t take any reduction in the slope factor; you must use \(C_s = 1.0\).

Source: NBCC 2020 - Figure A-4.1.6.16.(3)

Source: NBCC 2020 - Figure A-4.1.6.16.(3)

Key Load Considerations for Solar Panels

Here’s a high-level look at how these installations affect your design:

- Sliding and Concentration: For panels on a sloped roof, the code assumes snow will slide off the slippery panel surface and accumulate on the roof area just downslope. This can lead to a significant concentration of load. For some configurations of Parallel Flush panels, the accumulation factor, \(C_a\), can be as high as 2.0 on the roof area just below the panels.

- Drifting: Tilted panels on a flat roof act like a series of small, single-sloped roofs. Snow will be scoured from the windward side and deposited on the leeward side, and you’ll get drifts forming at the low edge of the panels. The code specifies an accumulation factor, \(C_a\), of up to 2.0 in the area just beyond the lowest edge of the panels.

- Sheltering: For Parallel Raised panels, the area directly underneath can be partially or fully sheltered from snow. The code allows you to consider this, but you need to account for the snow that does accumulate on the panels themselves.

Key Takeaway: The absolute most important rule is in Sentence 4.1.6.16.(1): you must determine the snow loads with the solar panels and compare them to the loads without the panels. You are required to design for whichever case produces the most critical effect. Don’t assume the solar panel case is automatically worse for every structural member.

The Deep Dive: Designing Snow Retention and Sunshades

Here’s where we get into some of the finer points that often get missed, and where experienced engineers can really add value and mitigate risk.

Snow Retention Systems (Snow Guards)

I mentioned that an “effective means” of snow retention is one way to avoid the sliding snow load case. But what does that mean, and how do we design these systems? This is another critical guard-related load case, similar to the often-overlooked in-plane forces on fall-protection guards that we also need to consider.

The NBCC Commentary provides some crucial guidance. To be considered effective, a snow guard system must be robust. The commentary suggests a guard made of horizontal rails with a minimum diameter of 25 mm, spaced no more than 100 mm apart.

But here is the single most important point for your design notebook:

CRITICAL DESIGN PRINCIPLE: Snow guards and their connections must be designed for the forces exerted by the full design snow load that could slide from the upper roof, even if the guards themselves aren’t tall enough to restrain that entire volume of snow.

Think about that. A thin layer of ice can form mid-pack, and the entire mass above it could slide as a slab. The guard has to be able to stop it. Preventing a few chunks from falling is not enough; the system needs to resist a significant structural load. The forces on the connections—the clips, the screws into the structure—can be enormous. Don’t just specify an off-the-shelf product; ensure it’s engineered for the specific loads on your project.

Sunshades and Ice Loads

Architectural sunshades are another feature that can pose a hidden snow and ice hazard. They look light and airy, but they can accumulate significant loads.

The NBCC Commentary has added specific guidance on this. Here are the key considerations:

- A sunshade should be treated as a solid surface for snow loading if the gaps between its slats are 100 mm or less.

- Even with larger gaps, if the sunshade is located below a sloped roof where snow and ice can slide off, it may behave as a solid surface as the sliding debris can bridge the gaps.

Wind-drifted snow from the roof surface has collected on the solar shade device, Source: The Construction Specifier

For a detailed methodology, the commentary points us to an industry standard: AAMA 514, “Standard Test Method for Static Loading and Impact on Exterior Shading Devices”. This standard provides a framework for testing and designing these elements to reduce the probability of failure from snow and ice. If you’re designing or specifying sunshades in a snowy region, this document should be part of your library.

Pulling It Together on Real Roofs

The roof is no longer a simple, flat plane. With every new feature we add, we’re changing the way it interacts with the environment. As engineers, our job is to stay ahead of these changes, understand the underlying physics, and apply the code with a healthy dose of practical judgment. These design challenges often arise on structures where Part 9 leans on Part 4 for complex small buildings, pushing us to apply these detailed Part 4 rules. The provisions in the NBCC and its commentary give us the tools we need to design safe, resilient structures that can stand up to a Canadian winter.

As you review your next roof layout—solar, guards, sunshades, and all—it’s worth asking which elements are quietly attracting drift and sliding loads and whether the current details really reflect the NBCC 2020 intent.