Following An Introduction to Performance Based Design, this article focuses on how to actually run a PBD project in practice—who needs to be involved, what process they follow, and how performance objectives are defined.

The sections below outline:

- The typical PBD workflow – think of it as your project roadmap.

- Who needs to be on your “PBD Dream Team” and what they bring to the table.

- How to actually set those all-important performance objectives with the client.

The PBD Workflow

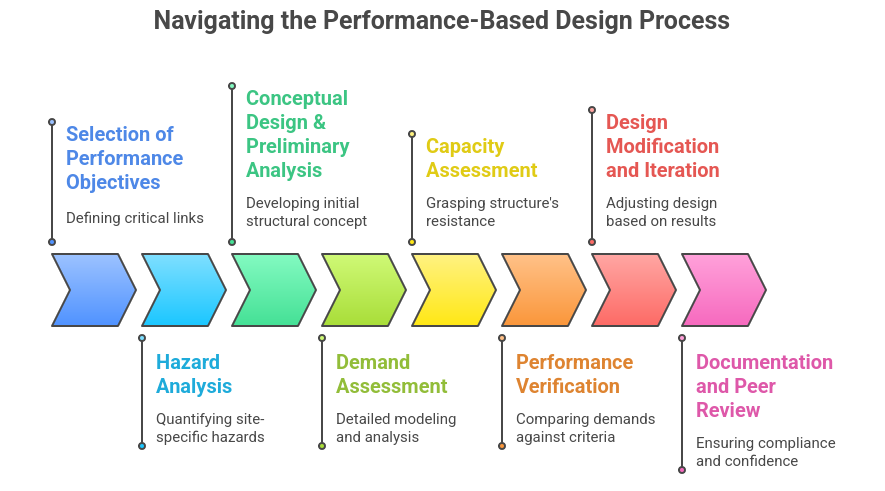

Think of undertaking a PBD project as a systematic journey. It’s not always a straight line – as we’ll see, iteration is key – but having a clear framework keeps everyone on track. While specifics can vary, the general PBD process usually unfolds like this:

Selection of Performance Objectives: This is ground zero and, honestly, one of the most crucial steps. It’s a collaborative effort involving you, the owner, the architect, and other key stakeholders. You’re defining those critical links: “For X Hazard Level (say, a specific earthquake return period), we want the building to achieve Y Performance Level (like Immediate Occupancy or Life Safety).” We’ll dig into how to define these objectives a bit later in this post.

Hazard Analysis: Once you know your targets, you need to quantify the specific hazards your structure will face at its particular site. For us in Canada, this often means a detailed seismic hazard assessment, potentially going beyond the general values in the National Building Code of Canada (NBCC) for site-specific PBD. Think about those PSHA or DSHA studies we touched on.

Conceptual Design & Preliminary Analysis: With objectives and hazards defined, you start developing the initial structural concept. This might involve some early-stage analysis to see if your chosen system is even in the ballpark for meeting the goals.

Demand Assessment (The Deep Dive Analysis): This is where the detailed modeling and analysis happen – often using those nonlinear static (pushover) or nonlinear dynamic (time history) methods we’ll discuss more in future posts. You’re figuring out the “demands” on the structure: the drifts, forces, deformations, etc.

Capacity Assessment: Alongside understanding the demands, you need a solid grasp of the structure’s “capacity” – its ability to resist those demands based on material properties, member detailing, and expected behavior (think plastic hinging in steel or concrete). Our fantastic Canadian material standards like CSA S16 for steel and CSA A23.3 for concrete are indispensable here.

Performance Verification: This is the moment of truth! You compare the calculated demands (from Step 4) against your pre-defined acceptance criteria (which come from your Performance Objectives in Step 1). Does it pass?

Design Modification and Iteration (The “Lather, Rinse, Repeat” Phase): If the verification shows your design doesn’t meet an objective, it’s back to the drawing board – or, more accurately, back to the model. You’ll modify the design (beef up members, change details, etc.) and then re-run the analysis and verification. PBD is often a loop until all objectives are met.

In practice: Expect at least a couple of design–analysis cycles. Building time for iteration into your schedule is just smart PBD project planning.

Documentation and Peer Review: Once you’ve successfully met all objectives, everything needs to be meticulously documented. For PBD projects, especially those using alternative solutions under the NBCC, a robust peer review by independent experts is almost always a must. This gives the Authority Having Jurisdiction (AHJ) the confidence they need.

Assembling Your PBD Dream Team

One thing you’ll learn quickly with PBD is that it’s definitely not a solo mission for the structural engineer. It’s a team sport, and clear, consistent communication is the name of the game. Here’s a look at your typical starting lineup:

The Owner/Client

They’re more than just the ones signing the cheques. The owner is critical in defining the desired performance. They need to understand what “Immediate Occupancy” versus “Life Safety” actually means for their investment, their operational continuity, and their risk tolerance. Your job is to help them understand the implications (cost, downtime, safety) so they can make informed decisions.

The Structural Engineer (That’s You!)

You’re the one translating the owner’s vision into tangible engineering. This means:

- Educating the owner on PBD.

- Guiding the selection of performance objectives and acceptance criteria.

- Overseeing the hazard analysis, detailed structural modeling, and nonlinear analyses.

- Leading the design iterations.

- Preparing the documentation and liaising with the peer reviewer and AHJ.

The Architect

The PBD approach can influence architectural choices, and vice-versa. The architect needs to be in the loop to ensure the design intent can be met while accommodating a structure designed for specific performance. Think about how non-structural elements (facades, partitions) will behave if you’re targeting higher performance – the architect plays a big role here.

Other Engineering Disciplines (MEP, Geotech, etc.)

If you’re aiming for “Operational” performance, it’s not just about the structure; Mechanical, Electrical, and Plumbing systems might need to stay functional too. This means their supports, anchorages, and the systems themselves need to be designed for the expected building movements. Your friendly geotechnical engineer is also key for that site-specific hazard and foundation modeling!

The Authority Having Jurisdiction (AHJ) / Building Officials

Since PBD often involves “alternative solutions” under frameworks like the NBCC (Division A, Section 1.2.), engaging the AHJ early and often is absolutely crucial. They need to understand and approve your PBD methodology. In many Canadian municipalities, they’re quite familiar with PBD concepts, especially for significant or complex projects, but don’t assume – communicate!

The Peer Reviewer(s)

A cornerstone of good PBD practice. Independent experts review your approach, assumptions, analysis, and conclusions. This isn’t about catching you out; it’s about quality assurance and providing confidence to both you and the AHJ that the design is sound and truly meets the objectives. EGBC, for example, has clear guidelines on when peer reviews are necessary in B.C.

Collaboration is critical: Successful PBD hinges on regular meetings, clear documentation, and a shared understanding of the project’s performance goals among all these players.

How Performance Objectives Get Nailed Down

We’ve mentioned “Performance Objectives” a lot. This is where the rubber meets the road right at the start of your PBD journey. Establishing clear, quantifiable, and agreed-upon objectives is fundamental. So, how do you actually do it? It’s usually a blend of these key drivers:

1. Building Use / Occupancy (Form Follows Function, and Performance!)

This is a huge one. What the building is for dictates a lot:

- Essential Facilities: Think hospitals, emergency call centres, fire stations. Under the NBCC, these often fall into “Post-Disaster” Importance Categories. For these, an “Operational” or “Immediate Occupancy” level after a significant event is often the goal. Lives and community resilience depend on it.

- High Occupancy Buildings: Schools, theatres, large office towers. Life Safety is paramount for rare events (the NBCC baseline), but owners might want better performance (like IO) for more frequent events to minimize disruption and protect their investment.

- Standard Commercial/Industrial: Here, the objectives might align more closely with the NBCC’s implicit Life Safety goal for the design-level earthquake (2% in 50 years). However, a specific tenant (like a data centre within a warehouse) might have much higher needs!

- Buildings with Sensitive Contents: Museums, labs with delicate equipment, or facilities with hazardous materials. Here, objectives might focus on limiting floor accelerations or specific drift levels to protect what’s inside, not just the structure itself.

2. Owner Requirements & Expectations (Beyond the Minimum)

This is where you listen hard to your client. They might have specific business continuity goals that drive a need for higher performance. Consider:

- Downtime Tolerance: How long can they afford for the building to be out of commission?

- Repair Costs: Are they willing to invest more upfront to save on potentially massive repair bills later? (This is a big part of the lifecycle cost argument for PBD).

- Reputation & Marketability: For some clients, having a “more resilient” building is a selling point or critical for their brand.

3. Societal Expectations & Regulatory Minimums (The Floor, Not the Ceiling)

Our building codes, like the NBCC, set a baseline. For seismic, this is generally Life Safety for the design-level event. Society rightly expects that buildings won’t collapse and will allow safe exit. PBD often aims to meet or exceed these minimums. As we’ve seen, NBCC 2020 even mandates higher performance (like “no structural damage” implying elastic response) for certain buildings under more frequent earthquake shaking.

4. Economic Considerations (The Balancing Act)

There’s always a cost-benefit discussion. A detailed PBD process can help owners make informed decisions by comparing the upfront investment for enhanced performance against the potential long-term savings from reduced damage, faster recovery, and lower business interruption losses. It’s about finding the sweet spot.

Your role as the structural engineer is often to be the trusted advisor here. You’ll present the options, explain the technical implications, and help the owner and the rest of the team land on performance objectives that are ambitious yet achievable, and appropriate for the project.

That’s the core of the PBD playbook when it comes to process, people, and performance targets. It’s a more involved—and often more rewarding—way to approach design, leading to structures that truly meet the needs of their users and the community.

For the technical side of the toolkit, PBD Toolkit Part 3: Analysis, Modeling & Verification digs into the types of analysis we use (pushover, time history), how we model for them, and the all-important verification step.