In our first three posts, we’ve journeyed through the “what and why” of Performance-Based Design (PBD), mapped out the typical PBD process and player lineup, and even gotten our hands dirty with the nitty-gritty of modeling, analysis, and verification. If you’ve been following along, you know PBD isn’t just a fancy buzzword; it’s a powerful approach to designing structures that meet specific, tangible performance goals.

But now, let’s bring it back to day-to-day practice. How does all this PBD work fit into our daily grind as Canadian structural engineers? What does the National Building Code of Canada (NBCC) have to say, and what hurdles and horizons should we be aware of?

PBD Within the Canadian Code Landscape

You might be thinking, “PBD sounds great, but the NBCC is pretty prescriptive, right?” And you’re not wrong – a lot of the NBCC provides clear, “deemed-to-comply” solutions. But here’s the kicker: our code framework is more PBD-friendly than you might realize.

The NBCC: An Objective-Based Foundation

At its core, the NBCC is an objective-based code. Division A, Section 1.2. is your golden ticket here. It explicitly allows for “Alternative Solutions” – meaning, if you can demonstrate that your design achieves at least the minimum level of performance required by the Code’s objectives and functional statements, you’ve got a path. This is the primary gateway for formal PBD projects that might step outside the standard prescriptive clauses.

In practice: If you’re considering a PBD approach as an alternative solution, early and open communication with your Authority Having Jurisdiction (AHJ) is absolutely critical. Bring them into the conversation from the get-go.

“No Structural Damage” – PBD Making Explicit Inroads in NBCC 2020

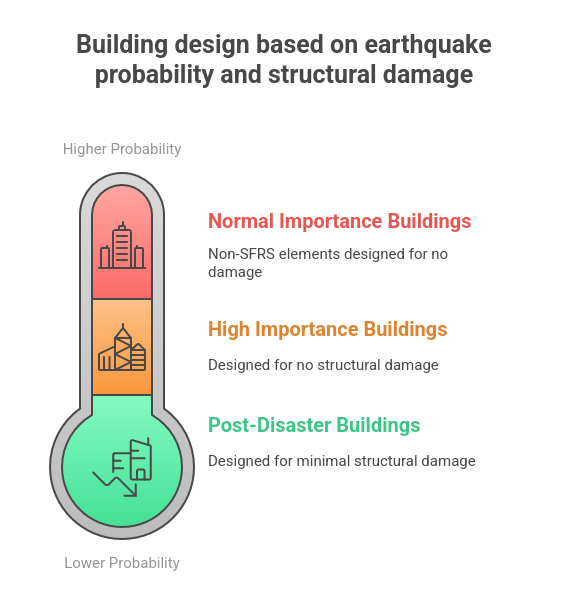

One of the most direct nods to PBD in the current NBCC 2020 (and something we expect to see continue or evolve in NBCC 2025) is Article 4.1.8.3A. This clause introduces a clear performance objective of “no structural damage” (implying elastic structural behaviour) for specific building categories under more frequent earthquake events than our typical 2%-in-50-years design earthquake.

Here’s a quick rundown:

- Post-Disaster Buildings: Must behave elastically (no structural damage) for earthquake demands based on a 5% probability of exceedance in 50 years in defined hazard areas.

- High Importance Buildings: Same elastic/no structural damage requirement, but for demands from a 10% probability of exceedance in 50 years earthquake in defined hazard areas.

- Some Normal Importance Buildings (>30m high): For these taller buildings in defined hazard areas, non-SFRS structural framing elements need to hit that elastic/no structural damage target for the 10%-in-50-years event.

This is PBD in action within the code. It sets a higher performance bar for critical structures and for non-SFRS elements in taller buildings under more “common” shakers, aiming to improve overall resilience and reduce post-earthquake disruption.

Don’t Forget the Commentaries!

The Structural Commentaries (User’s Guide – NBC 2020: Part 4 of Division B) are your best friend when navigating the nuances of Part 4. They explain the “why” behind the clauses and often provide guidance on application, including for advanced analysis. Keep an eye out for updates too – the committee structure includes a Task Group on Seismic Resilience and Performance-Based Design, which signals ongoing development in this space.

Material Standards

Our trusty material standards, CSA S16 for steel and CSA A23.3 for concrete, are essential allies in any PBD endeavor. They provide the rules for detailing members and systems to achieve the strength and ductility that a PBD approach often relies upon.

- CSA S16 (Design of Steel Structures): Think about section classifications (Class 1, 2, etc.) – these are direct indicators of a member’s ability to undergo plastic rotation, a key parameter in PBD. The latest CSA S16:24 even has updates specifically addressing those new “elastic behaviour” performance requirements in the NBCC.

- CSA A23.3 (Design of Concrete Structures): This standard is packed with detailing requirements for ductile concrete elements (moment frames, shear walls). The different ductility levels (Ductile, Moderately Ductile, etc.) defined in A23.3 are essentially performance grades. The 2024 edition, CSA A23.3:24, also includes new clauses to help apply the NBCC’s seismic performance requirements.

These standards provide the toolkit to design components that can actually deliver the performance you’re targeting in your advanced analyses.

Provincial Perspectives: EGBC Leading by Example

Here in British Columbia, Engineers and Geoscientists BC (EGBC) has also provided valuable resources that align with PBD principles.

- Their “Seismic Retrofit Guidelines” (currently SRG 2023), particularly for schools, are explicitly performance-based and have been for years. This sets a strong precedent.

- EGBC also has guidelines for “Performance-Based Seismic Design of Bridges in BC.”

- And don’t underestimate the importance of EGBC’s general professional practice guidelines, like those on Peer Review. Robust peer review is almost always a cornerstone of a successful PBD project.

Challenges in Implementing PBD in Canada

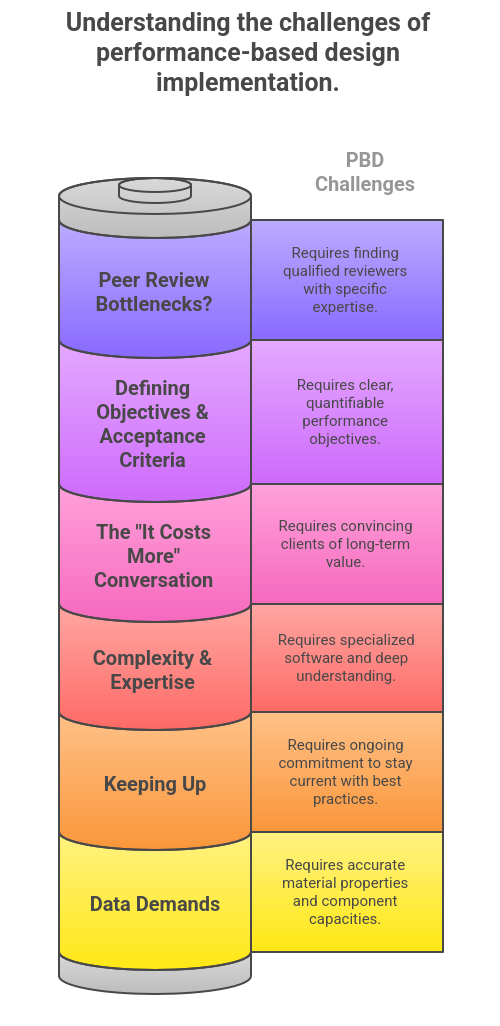

Okay, PBD sounds powerful, and the codes are opening doors. But let’s be real, it’s not always a walk in the park. Here are some of the common challenges we face:

- Complexity & Expertise: Let’s face it, nonlinear analysis (Pushover or Time History) isn’t as straightforward as running a linear static analysis. It requires specialized software, a deep understanding of material nonlinearity, component behaviour, and careful interpretation of results. Not every firm has readily available in-house expertise for the most complex PBD.

- Defining Objectives & Acceptance Criteria: This can be tricky. Getting clear, quantifiable performance objectives from a client requires good communication. Translating qualitative goals (like “minimal disruption”) into hard engineering acceptance criteria (e.g., specific drift limits, plastic rotation limits) can be challenging, especially if you’re dealing with performance levels beyond basic Life Safety. While documents like ASCE 41 help, tailoring criteria to a specific project needs careful thought.

- The “It Costs More” Conversation: PBD often involves more engineering hours upfront – for detailed modeling, multiple analysis iterations, and potentially more extensive peer review. Convincing clients that this upfront investment can lead to better long-term value (reduced damage, quicker recovery, enhanced safety) is key.

- Peer Review Bottlenecks?: While crucial for quality assurance, the peer review process can add time and cost. Finding qualified reviewers with specific PBD expertise can sometimes be a challenge for highly specialized projects.

- Data Demands: Good nonlinear analysis relies on good data – realistic material properties (especially post-yield and under cyclic loading), and well-understood component capacities.

- Keeping Up: Software evolves, research progresses, and codes are updated. Staying current with best practices in PBD is an ongoing commitment.

Key Takeaway: PBD demands more from us as engineers – more knowledge, more detailed analysis, and often more collaboration. But the payoff is a design that’s more explicitly tailored to desired outcomes.

What’s Next for PBD in the True North?

Despite the challenges, the future of PBD in Canada looks bright and full of potential. Here’s what I see on the horizon:

- Wider Adoption: We’re already seeing it with the NBCC 2020 changes. Expect PBD principles to become more mainstream, moving beyond just the iconic skyscrapers or ultra-critical facilities. The push for greater resilience will drive this.

- Resilience-Based Design: This is the bigger picture. PBD is a fantastic tool to help us design not just for individual building safety, but for broader community resilience – think quicker recovery times, maintained functionality of essential services, and reduced economic losses after major events.

- Enhanced Standardization & Guidelines: As PBD matures, we’ll likely see more standardized Canadian guidelines and pre-defined acceptance criteria for various performance levels and building types, making it more accessible.

- Integration with BIM & Digital Tools: The synergy between PBD and Building Information Modeling (BIM) is huge. Imagine more seamless workflows from model creation to advanced analysis and results visualization.

- Multi-Hazard Approaches: While seismic often dominates our PBD discussions in BC, the framework can and will be increasingly applied to other hazards like high winds, floods, and even fire, leading to more holistically resilient designs.

- Focus on Existing Buildings: Retrofitting our existing building stock to achieve better performance is a massive undertaking. PBD is absolutely central to making informed decisions about how and where to invest in seismic upgrades.

- Sustainability Links: PBD can contribute to sustainability goals by optimizing material use and by designing for durability and repairability, reducing the lifecycle environmental impact of structures.

Where This Leaves Us

Performance-Based Design is a journey, not just a destination. It challenges us to think more deeply about how our buildings should perform and to use our analytical skills to their fullest to achieve those goals. The Canadian codes are evolving, and as a profession, we need to evolve with them.

As you look at upcoming projects, it’s worth considering which ones genuinely benefit from a PBD approach and how early you can start aligning NBCC, CSA standards, and local policy expectations around that direction.